Environmental Performance in 2020

Certified performance

ISO 9001:2015 Quality Certificate

ISO 14001:2015 Environmental Certificate

iLOQ also requires that external manufacturing partners have an environmental management system that satisfies the requirements of ISO 14001 or another internationally recognized standard.

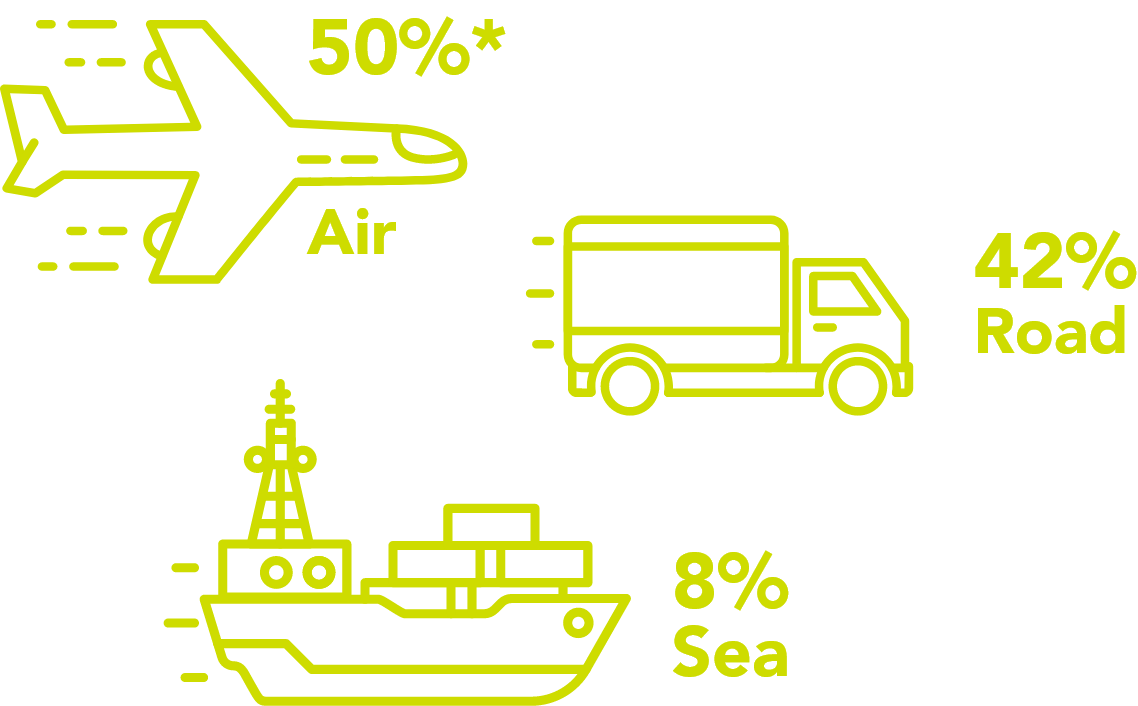

Effects of transportation

The outbound transportation mode for products from assembly to the customer is arranged at the request of the customer. Whenever possible, we recommend over land transportation over air freight. In 2020, we used more air cargo due to the COVID-19 pandemic.

Inbound & outbound transport share of parts and materials 2020:

*The share of air transportation increased in 2020 due to COVID-19, to secure our delivery capacity to end customers. Our goal is to balance this share with maritime transport during 2021, if the COVID-19 pandemic allows it.

The number of kilograms of cargo increased by 19.67% from 2019 to last year. Correspondingly, the amount of euros used for freight increased by 74.8% from 2019 to last year.

| Kg / % | |||

| 2018 | 2019 | 2020 | |

| Air | 19 % | 45 % | 50 % |

| Sea | 25 % | 12 % | 8 % |

| Road | 56 % | 42 % | 42 % |

258,265 kg of cargo

308,797 kg of cargo

Efficient utilization of

materials and resources 2020

Materials: Metals and plastics

iLOQ concentrates on efficient use of raw materials and the recycling of process waste whenever possible. Raw materials only account for 1–3% of the total cost of our standard Oval and DIN locks.

Packaging: Recyclable board

All iLOQ products are shipped from our assembly plant in packaging made of recyclable cardboard. Inbound components are also mostly shipped in recyclable packaging.

Energy: 46 000.00 € (estimate)

iLOQ Group’s (HQ and all subsidiaries) energy consumption consists primarily of data, HVAC and lighting, as well as assembly and R&D functions at the Oulu, Finland HQ. In most cases electricity is included in the rent, thus the figures are based on estimates.

Water: No water used in our processes

iLOQ’s product assembly processes do not use any water. Water consumption at iLOQ facilities is restricted to regular office use. The use of water in different iLOQ premises is included in the rent, providing no specific data on actual usage.

Recycling and waste

Recycling and waste

management

Taking advantage of UPS’ carbon-neutral program, iLOQ offsets emissions from its courier and parcel transport to verified environmental projects where methane is turned into biogas for heat and electricity production.

Through Kuehne+Nagel’s Net Zero Carbon environmental program, iLOQ offsets emissions from its transportation to verified environmental projects that absorb carbon dioxide from the atmosphere.

Product Sustainability

No batteries

All iLOQ digital locking solutions are self-powered, with the power needed to confirm access rights and open the lock coming either from the kinetic energy produced by the motion of inserting the key into the lock (iLOQ S10) or from a smart phone used for access (iLOQ S50). This unique feature allows our customers to eliminate the need for a huge amount of battery waste each year.

Reusable and reprogrammable keys

All iLOQ keys are reusable and reprogrammable. This means that instead of becoming waste, they can be reallocated to work with a new or different set of locks within the same system. Reprogramming also includes blacklisting lost or misplaced keys, which eliminates the need for changing out entire locks for security reasons. This is how the smart digital nature of iLOQ solutions helps save raw materials in everyday use.

Digital is environmental

Cloud-based digital access management reduces the number of needed physical local servers. Not only does this reduce the amount of physical hardware, which eventually ends up as electronic waste and scrap metal, it also optimizes the consumption of energy. Running one server rather than thousands of separate local servers, we are minimizing the amount of wasted energy. A local server, which spends 90% of the time powered up but inactive/on standby, still consumes energy for basic functions as well as cooling. Smart and secure cloud-based server solutions can drastically reduce energy consumption across the board.

Built to last and perform

Creating durable and virtually maintenance-free products and solutions with an extended lifecycle means a reduced need for materials and hardware, as well as installment and repair -related travel, over the lifetime of your iLOQ solution.